Setting New Standards for Machine Vision

Monode has a long history of innovation in the machine vision field. We've helped write and maintain several key industry standards, and pioneered a patented software solution that integrates the marking and vision processes.

Our experise in marking processes has made us strategic partners with most of the top vision companies, whom we've partnered with to improve algorithms used to read marks across a wide spectrum of types, materials and quality levels. Our marking labs are commonly utilized by vision companies for research and development of new algorithms and processes.

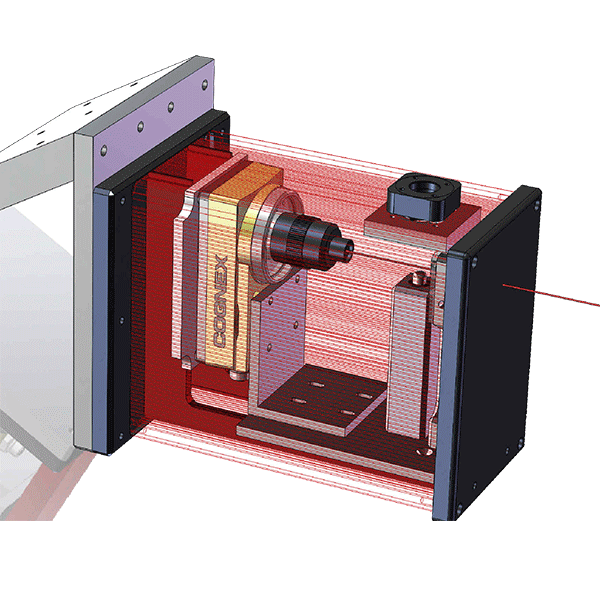

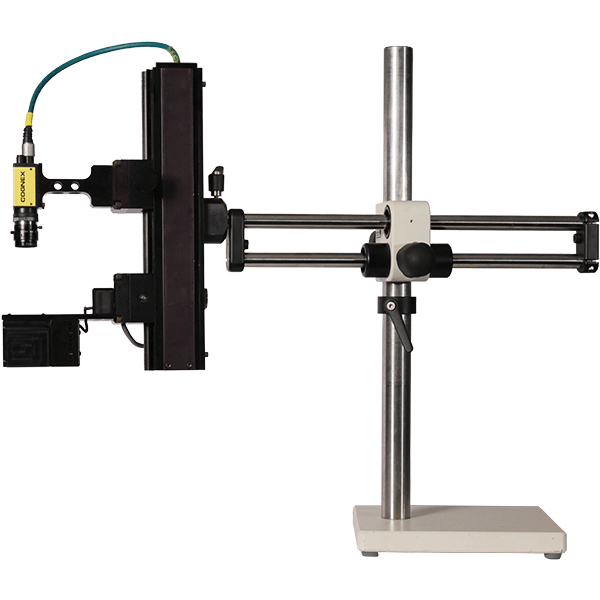

Manufacturing processes which require tedious manual inspection can benefit from the precision, accuracy and increased throughput gained from automated machine vision part inspection systems. Machine vision technology enables organizations to comply with configuration and quality management requirements for the identification and traceability of components throughout the manufacturing process.

Common uses for machine vision include:

- Aerospace – All parts that fall under MIL-STD-130 / ATA Spec 2000; engine parts

- Automotive – Used for unit level traceability and inspection of most parts

- Power and Gas – Blades, vanes and lifecycle tracking

- Medical Devices – Surgical instruments and implants