Manual and Pneumatic Steel Stamp Impact Presses

Monode's manual and pneumatic impact presses provide the versatility needed in your manufacturing operation. Whether your need is marking, piercing, shearing, punching, forming, stamping or assembly, a Monode impact press will meet all your needs. Our unique impact spring design provides consistent pressure from piece to piece, even with variations of the air pressure or operator input.

Features include:

- Easy height adjustment

- Heavy duty construction

- Precise marking force

- High production

- Minimum maintenance

- Lower marking costs

- Safe and simple to operate

- Easy installation

- Wide range of applications

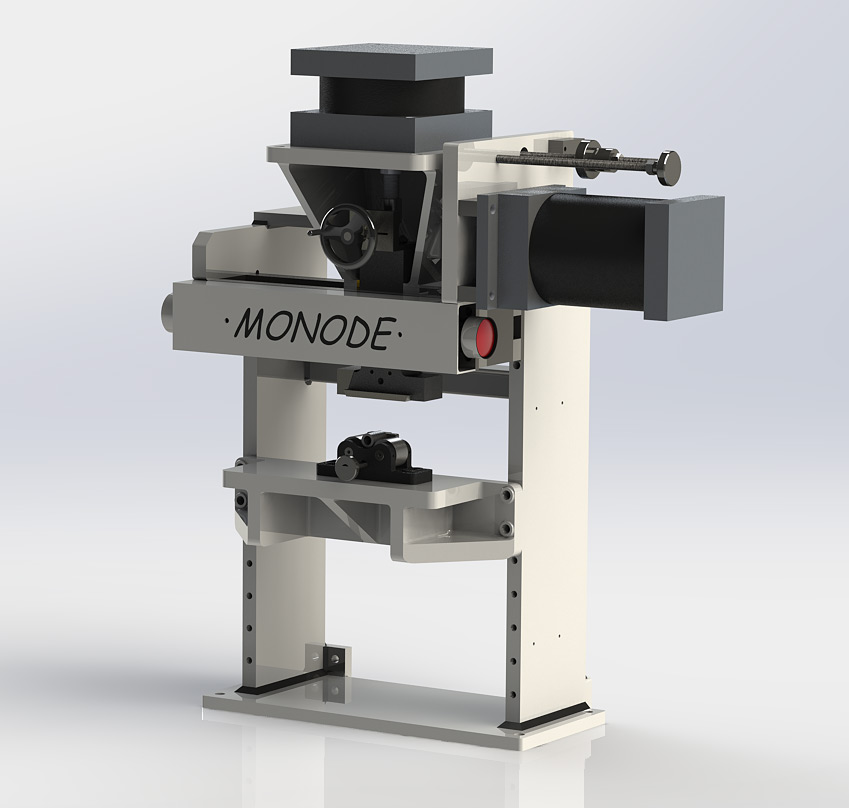

PR-320 Pneumatic Roll Marker

This pneumatic roll marker adds versatility and efficiency to steel stamping operations. It can be operated in any position to fit specific applications, such as marking components on transfer type machines.

The PR-320 accepts existing roll marking machine tools, or can be equipped with Imperial's standard line of fixtures.

The PR-320 uses flat stamps or marking rolls to mark round, flat or contoured surfaces. The marking head automatically moves down against the piece part, applies controlled pressure, and rolls from right to left across the work, producing the highest quality impressions. With large die space and a hand wheel for fine depth adjustments when required, a variety of sizes can be marked.

Its unique, rugged design provides advantages normally associated only with larger, more expensive machines. An "H frame" construction with open back makes it easy to accommodate longer parts. A sturdy, completely-enclosed base reduces space requirements. Hand controls are within easy reach of the operator. The unit is pneumatically operated with horizontal and vertical cylinders in the marking head – once the part is located, it remains in a fixed position.