Photosensitive Stencils

Monode's photosensitive stencils are a photographically-processed stencil medium manufactured in-house at our facility. The tough lacquer base of these stencils provides a stencil medium that will last for thousands of marks.

All varieties below are available in standard sizes of 2½ X 7", 3¼" x 7", 5 X 7" and 8 X 10". Custom sizes are available upon request at a premium price.

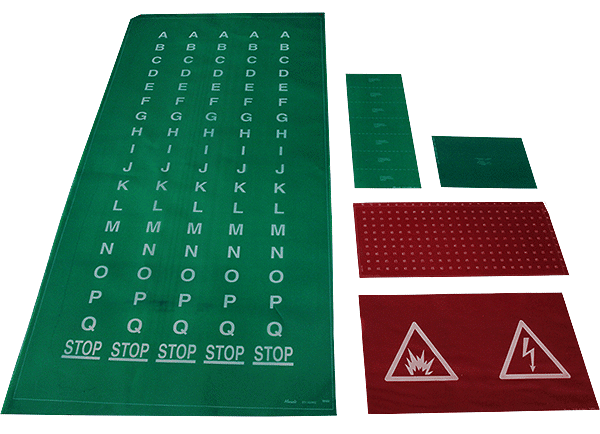

Dura-Fab Stencils – Type DF

The toughest of all electrochemical etching stencils, these are constructed on a synthetic woven fiber base. Because of the relatively heavy diameter of the woven fibers of these stencils they are recommended for stencil designs with features that are at least 3/32" deep.

Dura-Fab Fine Stencils – Type DFF

Same as the DF stencil but with a finer, closer synthetic fiber base weave. Ideal for fine lines or detailed art work.

Please Note:

More information about this product is needed in the note section. Please tell us the exact part number or description of product in the final request a quote form on the following page.