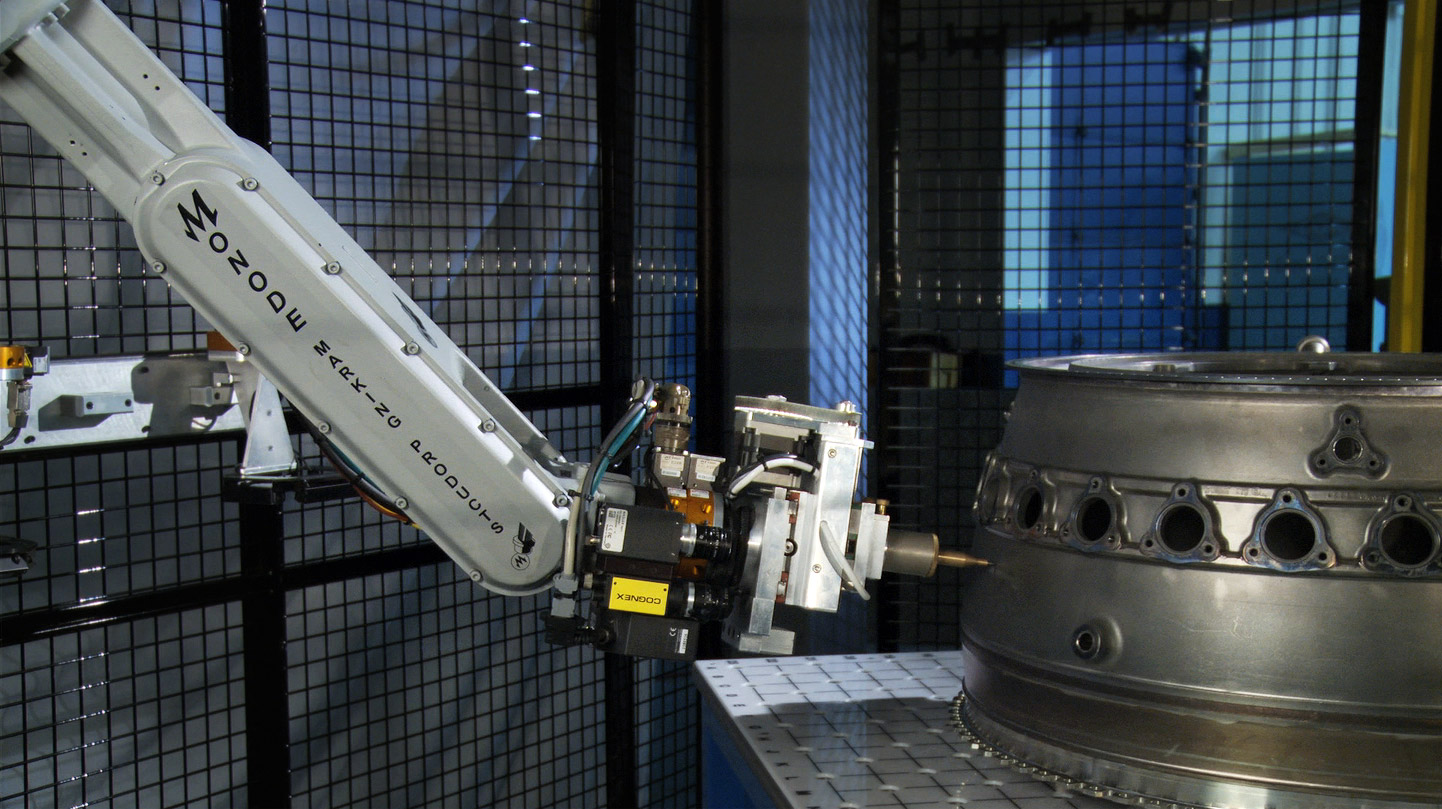

The world's first completely vision-guided robotic marking system featuring marking and verfication of both pin geometry and mark quality.

Aerospace is in our DNA

Monode owes its very existence to the aviation industry. During World War II, most aircraft engine component failures were due to stress fractures caused by molecular deformation at the site of hand-stamped indent marks. The Army Air Corps commissioned several Cleveland-based engineering groups to study the problem and find alternative methods by which to mark these critical components. From this research request the etching industry was formed, and since the post-war period Monode has continually been recognized as a leader in marking technology for aerospace.

Aerospace presents us with a number of unique challenges: a wide complexity of geometrical shapes, advanced metals and super alloys, and the importance of flight critical or safety critical components where traceability and accountability go hand in hand.

When it comes to marking parts, the aerospace industry tends to focus on quality versus speed. Given the high cost of components, most aerospace applications require a perfect mark every time with no escapes.

We work with every engine manufacturer and are members of standards groups with Boeing, the United States Air Force and NASA. Our goal at Monode is to mark every part that the aerospace industry presents to us. We have risen to that challenge every time with some of the marking industry's most innovative solutions.